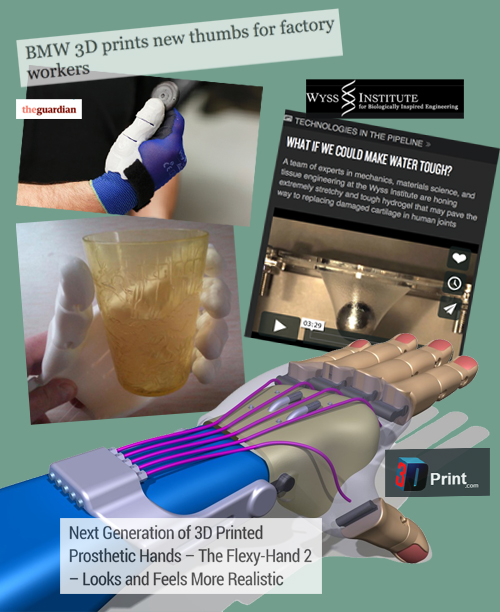

| A couple of months ago, I spent a mindblowing weekend reimagining space suits as part of Team Sentio for a science hackathon at Chicago’s Adler Planetarium. Our goal was to turn things inside out: Instead of creating a protective cocoon that restricted movements and blunted senses, we set out to design a suit that would improve mobility, increase dexterity, and expand sensory awareness. We modeled synesthesia, assigning new functions for senses underused in space (e.g. hearing solar wind, feeling cosmic rays). We engineered empathy, connecting team member sensors so individual experiences could be shared. And we spent a lot of time thinking about the evolution of the human hand, both past and future. "…Darwin was the first to speculate that toolmaking could have played role in developing the shape of the human hand, which is unique among primates and, indeed, unique among all species. It turns out he was right. Our destiny has literally always been in our hands. Yet while human hands are exquisitely adapted to life on Earth, new hands with new abilities will likely be required for life beyond our planet. For that, evolution will need a jumpstart…” --Science Hack Day Chicago 2014: Reinventing the Space Suit, Cosmic Biomicmicry and the Joy of Thinking Different Engineers here on the home world, though, impatient with the ploddy process of natural selection, have beaten us to the punch. To evolve a thumb better suited to build BMW cars the old fashioned way would require tens of thousands of years, for example, so the ever-practical German car manufacturer turned to CAD and 3D printing to create a thumb worthy of Iron Man himself. They took a cue from invertebrate exoskeletons—which are so exquisitely custom fit, they are shed once outgrown—scanning each worker’s thumb to fabricate an orthotic perfectly tailored to the individual. A process called selective laser sintering was used to print out the exo-thumbs combining hard plastic and soft silicone. "The finished thumb guard flexes in a closed position. But because the structure is perfectly fitted to the wearer’s thumb the pieces lock into place when the digit is raised into a thumbs-up position. The locked splint resists strain and spreads the load of pushing something like a stiff rubber plug into holes in the car’s chassis – something that was causing pain and strain for production-line workers." — BMW 3D prints new thumbs for factory workers FLEXI-HAND v.2 It is one thing to augment a digit and quite another to take on a whole hand. When first introduced last spring, the Flexy-Hand prototype was immediately recognized for pushing the boundaries of prosthetics, which is saying something considering all the amazing stories of international collaborations over the last year designing 3D printed Robohands. Using a a new elastic filament called Filaflex, the Flexy-Hand is modeled to look more like a real hand, complete with fingernails. Its second iteration includes an attachment mechanism. The design has been uploaded to Thingiverse, so anyone can customize and improve it. At a materials cost of less than $30, plus a little maker know-how, who couldn’t use an extra hand or two? In fact, Team Sentio discussed the possibly of adding extra hands, arms, legs and even a tail to our souped up spacesuits. Why should octopi have all the multi-limb fun? WITH FEELING…. While an autoworker kitted out with a BMW exo-thumb still has a muffled sense of touch, an artificial hand offers none, providing mechanical functionality but no sensory awareness. Yet hands are central to much of what we know about our environment. Through our fingertips we know whether a texture is smooth or rough, wet or dry, cold or hot and all the subtleties in between. We can feel the springiness of a computer keyboard and the connectedness of holding another’s hand. The next big advance in prosthetics will bring touch into the equation. It is already beginning to happen with reports of experimental surgery connecting electrodes to nerves in an amuputee’s upper arm. But imagine if an artificial hand were made of material that felt more like a real hand, mimicking the plasticity of human tissue and laced with a network of sensors. One such material candidate might be a new kind of hydrogel nicknamed “tough water,” a super-absorbent hybrid polymer scientists at Harvard’s Wyss Institute for Biologically Inspired Engineering have been investigating. Tough water is as unlikely as it sounds: a material made up mostly of water—just like us—that returns to its original shape after being stretched—just like rubber or silicone. "The water nature of the hydrogel might allow us to deliver drugs directly through it. So in the case of burn patients who wear compression bandages to reduce scarring, could we use this material for that? What if we were able to use a material like this stuff, hydrogel, in a 3D printing system to actually print vessels, organs, ligaments and things along those lines? We could potentially actually print a meniscus to place in a damaged knee. You would actually print this shape and actually implant it and hopefully cells migrate into it and replace it. I think that would be the ultimate goal of a technology like this." —Edward Doherty, Wyss Institute Tough water is still a laboratory curiosity, but its potential is impressive. Imagine Flexy-Hand (v. 57…) printed with a tough water filament, fitted with thin carbon nanotube transistors wirelessly linked to a nervous system. It might not be the same as real hand, but then it might be better, able to sense things that we cannot and connect in ways we cannot yet fathom. Even Iron Man could use a few of those. — J.A. Ginsburg RELATED:

|

|

0 Comments

Your comment will be posted after it is approved.

Leave a Reply. |

BackgroundDot to Dot grew out of the TrackerNews Project, a demo news aggregator developed for InSTEDD, an independent spin-off of Google.org's humanitarian practice that focused on health issues, humanitarian response and technology. Archives

• Bats, Trees And Bureaucrats: Ebola And How Everything, Positively Everything, Connects • Scrubba Dub Carlos and the Big Bad Enterovirus: Why Sneeze When You Can Sing? • Ebola, Bats and Déjà Vu All Over Again • Scaling Good: Project Frog’s Buildings And The Kitchen Community’s Learning Gardens • Thumbs Up And High Fives: Evolution, Hands And 3D Printing • Legos, Makers, Molecules, Materials And The Very Big Business Of Small Things • Solid: When Bits and Atoms Dance • Science Hack Day Chicago 2014: Reinventing The Space Suit, Cosmic Biomicmicry And The Joy Of Thinking Different • The Motors of August Cicadas • Mulling Snow, Climate, Pain Points, Bootstrapping And Chicago’s Advantage • Glass, Tech And Civilization: The Material That Makes Just About Everything Better • A Tale Of Two Maps And Why You Can’t Teach An Old Grid New Tricks • When Bad Things Happen To Good Content: Form(At), Function, Perspective And Possibilities • The Sum Of Its Parts: Autozone Meet Autodesk (Please) / On Supply Chains, Carbon Footprints And How 3D Printing Can Change The Game (Again) • It Takes An Economist: Tallying Natural Capital • Beyond Measure: Da Vinci’s Genius, Peripheral Vision, The Prepared Mind, Metric Traps And Hacking The Filter Bubble A Solstice Encore: Imaginary Carl Sagan, A Holiday Mix Tape And The Tannahill Weavers Categories

All

|

RSS Feed

RSS Feed